The future of freshness

We all enjoy fresh, delicious and nutritious food that keeps us healthy. With the rising demand for greens and vegetables due to population growth and increased health awareness, agriculture is evolving. The quality of produce depends not only on skilled gardeners, but also on innovative greenhouse technology. At Finngrowers, we’re leading this change for the better.

With over a decade of expertise in successfully growing various crops and developing state-of-the-art greenhouse technology, we offer comprehensive solutions for all stages of farming. From turnkey greenhouse development and construction to gardening as a service (GaaS) – with packaging, marketing and sales – we’ve got you covered.

We bring farms to people

At Finngrowers, we aim to revolutionize traditional farming. Instead of relying solely on often distant rural areas with ideal soil and climate, we bring farms closer to the people.

With traditional farming, transportation increases costs and decreases freshness. Too often we don’t know where our food comes from, how it has been grown and when it was harvested. The changes in weather affect crop quality and lead to heavy pesticide and fertilizer use, burdening the soil and groundwater. We aim to change all this.

An endless growing season, close to the customer

Imagine having a 365-day growing season right where you live, with fresh, nutrient-rich local produce every day – produced by farmers you know. At Finngrowers, we make this a reality. Our technology-driven local farming concept brings farming closer to everyone, anywhere in the world, ensuring freshness and transparency in every bite.

Path to a greener future

We are dedicated to transforming traditional farming through controlled environment agriculture (CEA). We have over 40 years of experience in greenhouse production and farming, honed in the harsh climate of Finland. This enables us to produce consistent quality with a profitable cost structure – in an environmentally friendly way.

Growing with our innovative CEA technology

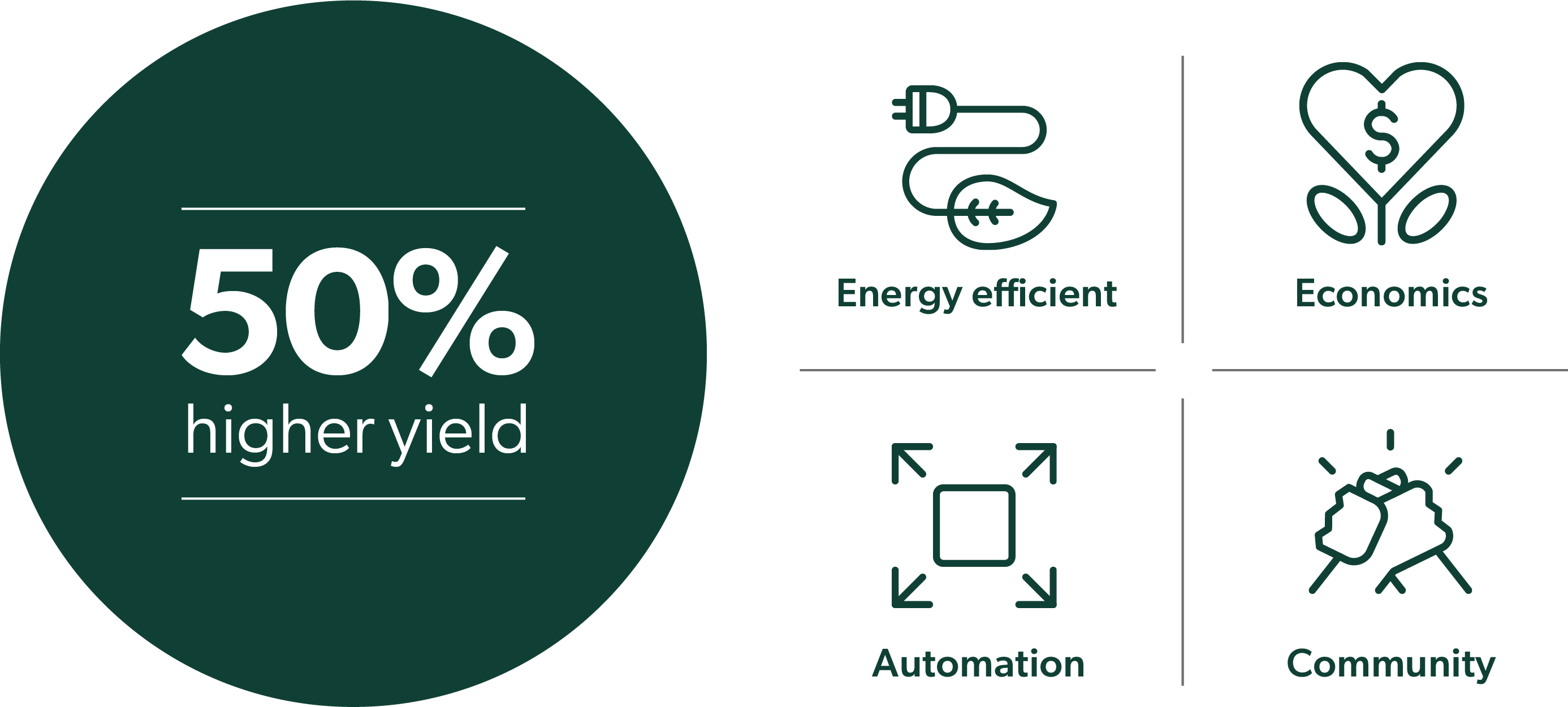

For the past eight years, we’ve focused on developing CEA technology for subtropical climates and pioneering closed environment farming. Our patented climate control system allows us to create an optimal growing climate anywhere, with the lowest energy costs on the market. Our technology has proven successful in both northern and southern hemispheres, including vertical farms and traditional Venlo glasshouses.

Sustainably produced greens for everyone

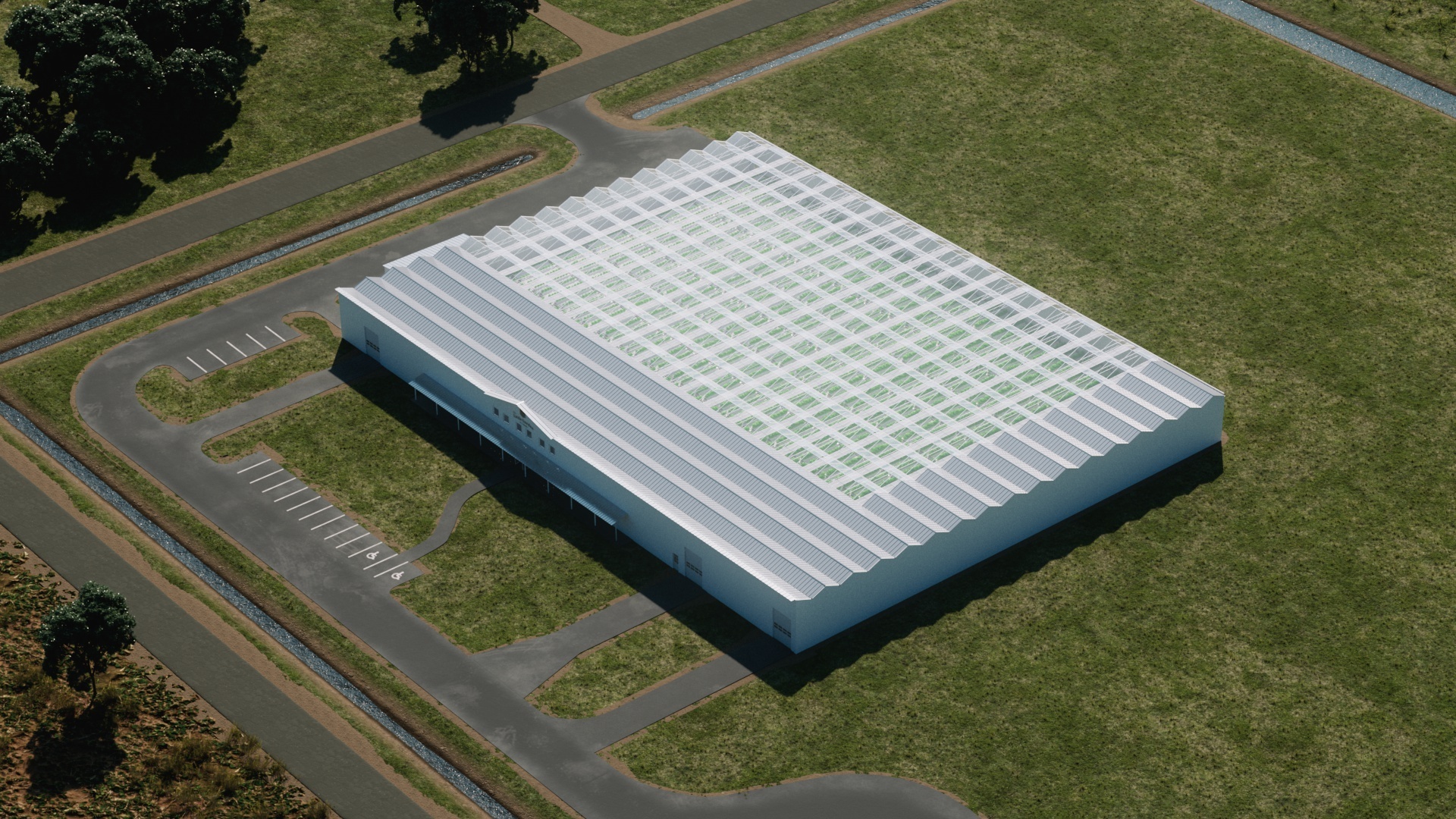

We believe that truly fresh and healthy, sustainably produced greens should be attainable for everyone. Our modular greenhouse concept allows our clients to grow their favourite high-quality crops right where their customers are.

With our technology and growing expertise, we can build high-yield CEA farms anywhere in the world. The farms will be strategically located close to customers, achieving high yields with low energy consumption, and producing more for less – for everyone.

New business models with turnkey services

We plough the path to the greener future by with our innovative technological solutions and turnkey services that work for everyone from farmers to investors. Our comprehesive greenhouse concepts include development, construction, gardening as a service (GaaS) guidance, and help with packaging, marketing and sales.

One of our business concepts is a modular model for multi-greenhouse production which allows for a subscription-based delivery service. The concept provides fresh greens that are harvested close to the customer for best taste and freshness.

We are constantly developing not only our innovative technology, but also novel concepts and business models. Let us help your investment grow.

We believe fresh, healthy greens should be available for everyone. That’s why we strive to make our production truly local.

Why Finngrowers?

We Finns are known for our honesty and reliability – and our ability to grow things in extremely challenging climates. At Finngrowers, our innovative technology and service concepts enable the growing, selling, and delivery of fresh, local crops with better taste, nutritional value, and shelf life. That’s the fresh difference.

Our key differentiating factors

- Finnish world-leading agricultural know-how in CEA farming and technology with 40 years of experience

- Own patented climate control technology

- Low CAPEX needs and efficient design

- Multi-vegetable production

- Production anywhere in the world – even in tropical climates

- Industry-leading energy-efficiency

- Short transportation distances

- Always fresh produce

Technology benefits

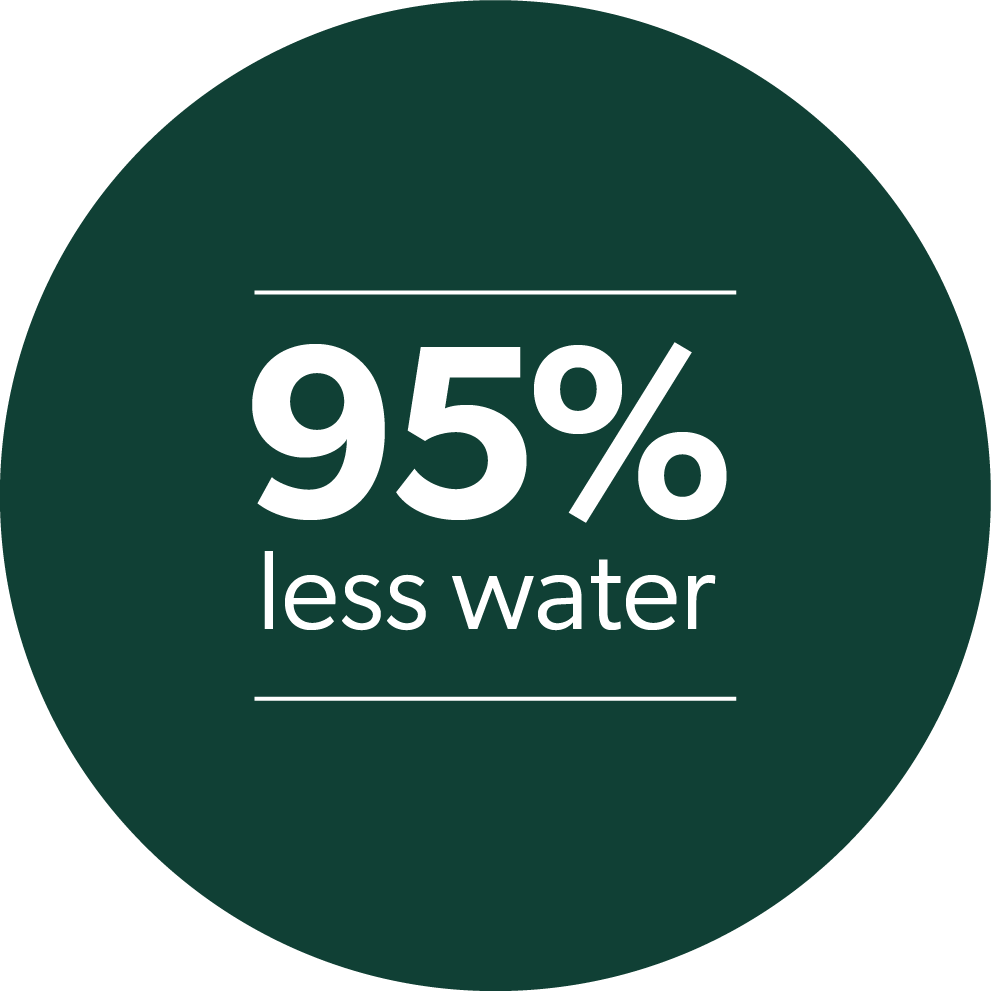

The technology used by Finngrowers has several benefits:

- Leading energy efficiency (energy cost $0.06 per lb) – critical in order to reach profitability

- Allows for production 365 days a year

- Highly efficient production with high yields – even in tropical climates

- Controlled environment omitting risks of spoiled crops

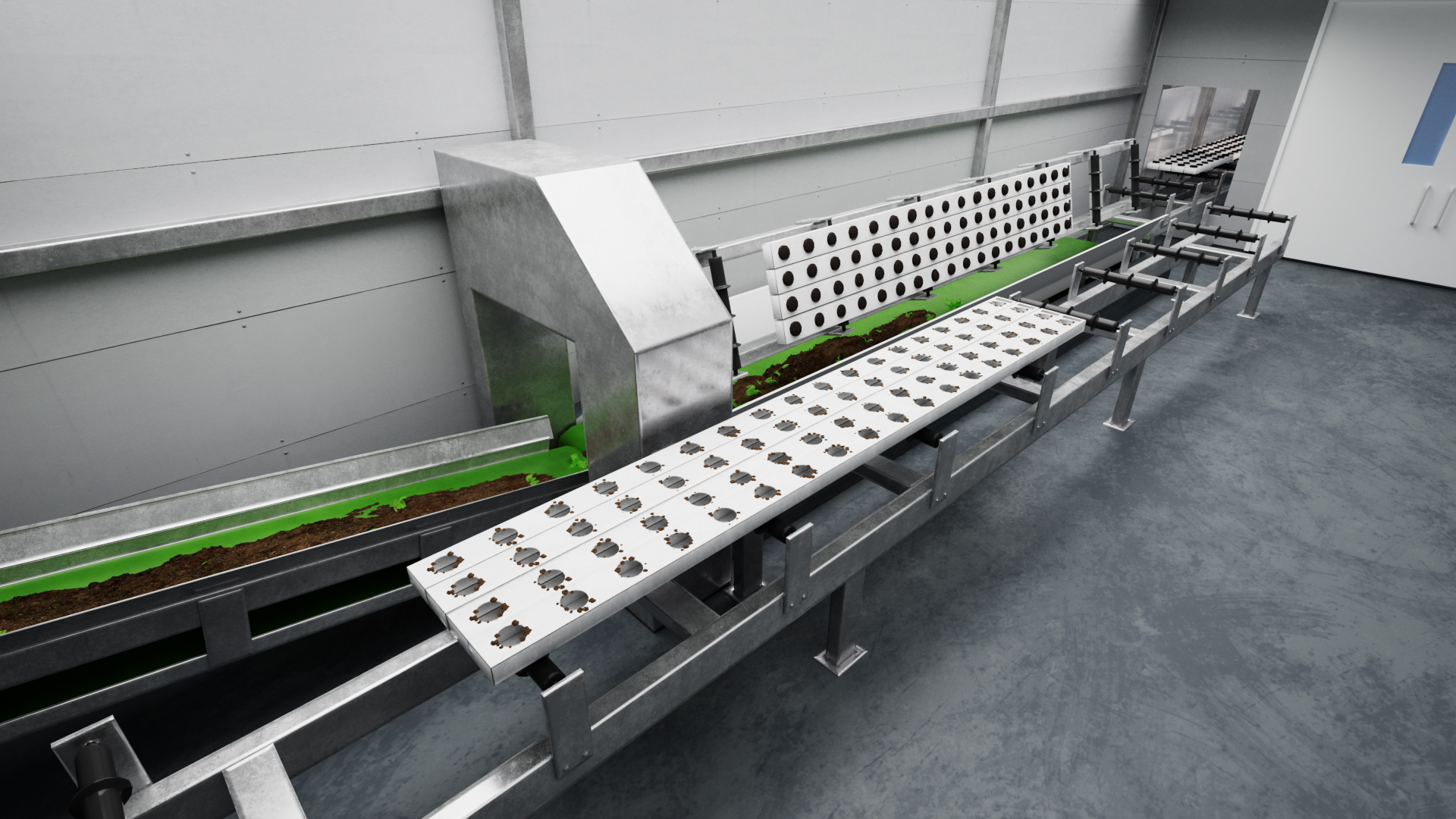

- High degree of automation significantly reduces the need for manual work

- Our automated cutter growing system the most flexible in the market, allowing the growing of multiple varieties simultaneously

Changing the U.S. market

Let’s be honest: greenhouse production in the U.S. is highly underdeveloped. Europe has 210,000 hectares of greenhouses, while the U.S has only 14,000 hectares. The U.S. is a huge importer of greens and vegetables, as domestic production is far from up to par with the demand.

Let’s look at an example:

- U.S. growers produce 3.8M TONS of lettuce annually, while the annual consumption is 4.7M TONS annually

- 89M TONS of leafy greens is imported to the U.S., with a market value of $5B

- To produce the imported amount, it would take 2,000 acres of modern CEA greenhouses

And this is just one example. In other words, there is enormous potential on the market – and this is where Finngrowers come in.

How Finngrowers can change the U.S. market

- With our scalable model and previous experience, we are able to build greenhouse facilities for every state and every climate.

- Our model is not limited only to leafy greens since our production consists of tomatoes, cucumber and berries.

- One greenhouse acre can produce same amount as 60 acres of open farmland.

- As farming can take place anywhere, the transportation costs become minimal, allowing for fresher product, smaller environmental footprint and less waste.

- With our technology, we are able to shrink down the production costs and minimize the energy costs to less than $0.06/lbs.

- Greenhouse production provides a great working environment and requires a fraction of traditional labor costs because of the high level of automation and yield.

- Our leafy greens production model allows to grow multiple of crop types – and change from one type to another, if needed.

State-of-the-art patented technology

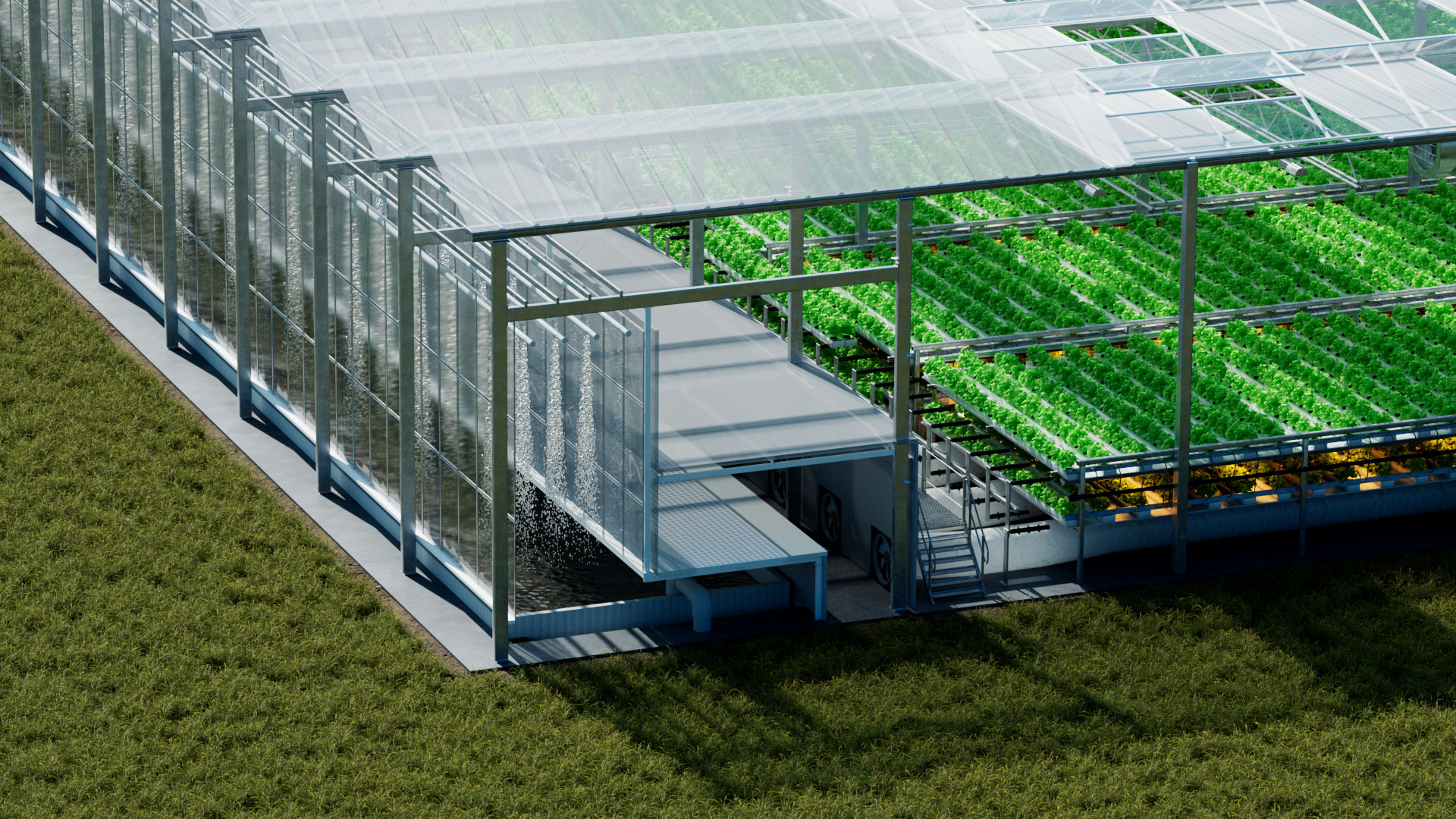

Our patented climate control technology enables sustainable climate control in greenhouses and vertical farms. The innovative system includes cooling, humidity removal and reuse, and heat reuse.

Our patented climate control system in a nutshell

- The heart of the Finn Growers climate control system is cold water droplet curtains that collect heat and humidity from the greenhouse to a water collection system.

- The system uses cold water basins (1000m3 per hectare) to create cold (15C / 59F) water, with or without chillers and cooling towers (depending on climate).

- When heat is transferred to water, the greenhouse can reuse the heat and utilize this in heating pipes (for e.g. cucumber and tomatoes), as well as heating water for sanitation.

- The system allows to have a closed greenhouse without any ventilation. This allows for an extremely high CO2 level inside the greenhouse that helps crops to grow quicker and tolerate higher tempereratures. With a closed greenhouse there is no need for pesticides.

- The system converts the humidity into irrigation water. This way the greenhouse doesn’t need any makeup water.

- The climate control system has been tested and proven to work globally in all weather conditions: cold climate (Finland), Mediterranean (Spain) and tropical (Florida).

Contact us

More information

Follow our journey and updates from the news below and by following us on Facebook!

Suomalainen kasvihuoneteknologia kiinnostaa Yhdysvalloissa ja Intiassa – osaamista ja teknologiaa halutaan viedä lämpimiin maihin

Ryhmä intialaisia ja yhdysvaltalaisia liikemiehiä vieraili Suomessa useissa kasvihuoneissa. Suomalaista kasvihuoneteknologiaosaamista halutaan viedä myös subtrooppisiin ilmastoihin.